- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

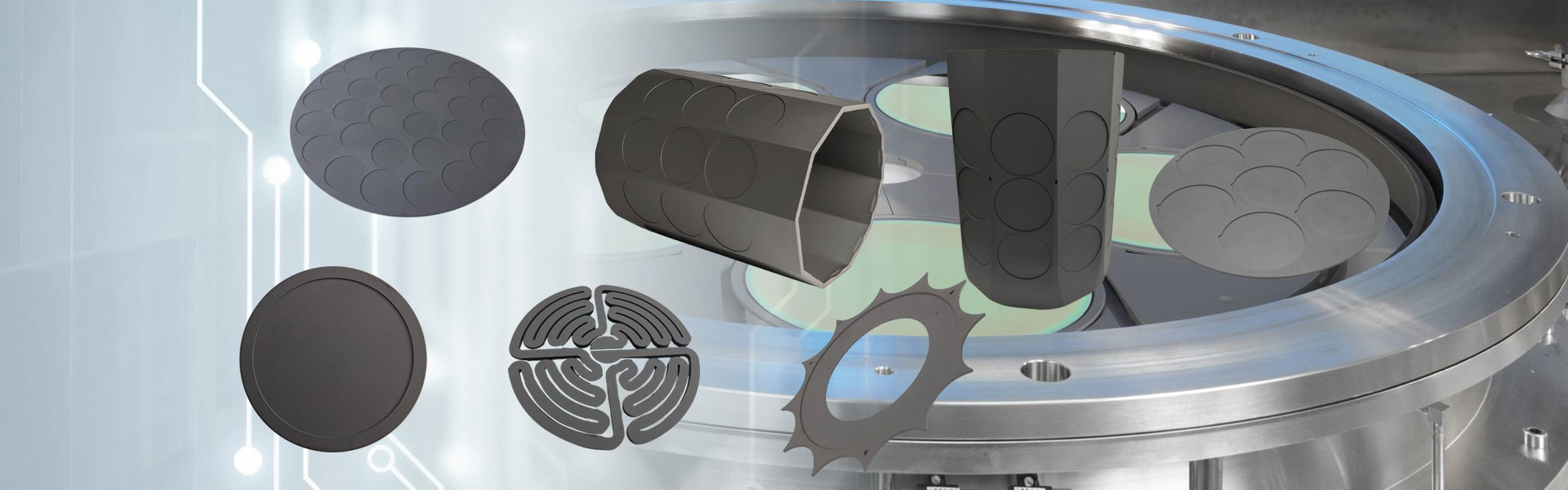

China Grafit isostatik Pengilang, Pembekal, Kilang

- View as

Bushing Grafit Gangsa

Semicorex Gangsa Grafit Bushing mempunyai ciri-ciri kapasiti beban tinggi, rintangan impak, rintangan suhu tinggi, keupayaan lubrasi diri yang kuat, dan juga dapat menahan hakisan dan menghisap cecair menghakis. Bushing grafit gangsa ini sangat sesuai untuk peralatan yang beroperasi di bawah keadaan kerja yang kompleks di mana minyak bebas minyak, suhu tinggi, beban tinggi, kelajuan rendah, anti-fouling, anti-korosi, dan persekitaran anti-radiasi.

Baca LagiHantar PertanyaanGalas lubricating diri

Semicorex Bearings Lubricating sendiri adalah sejenis galas yang menggabungkan sifat-sifat lubricating bahan grafit. Mereka digunakan secara meluas dalam bidang perindustrian dengan keperluan pelinciran yang tinggi dan keadaan persekitaran yang kompleks.

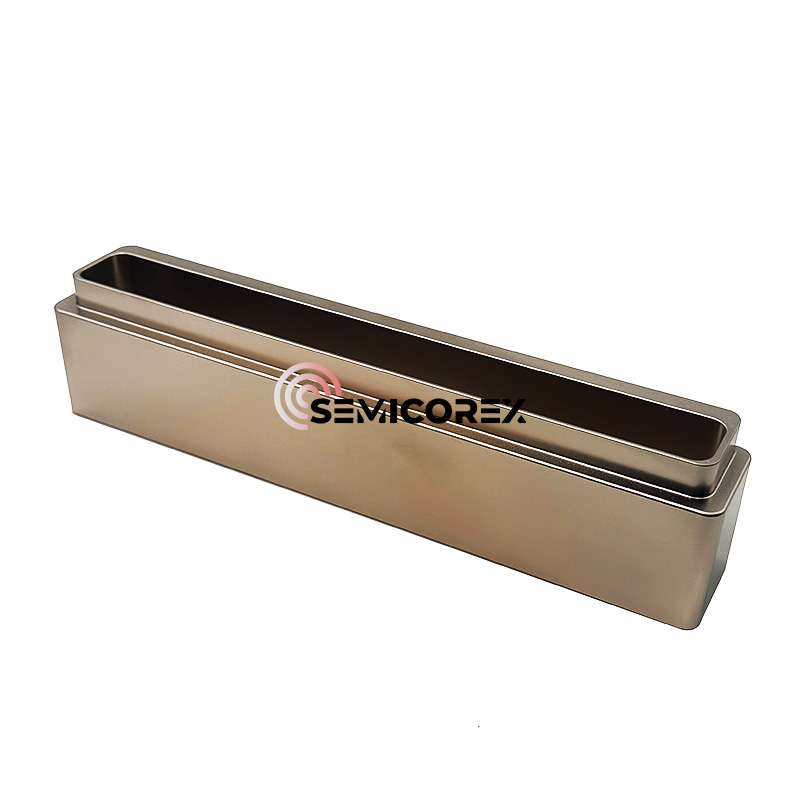

Baca LagiHantar PertanyaanPemanas Rod Grafit

Pemanas Rod Grafit Semicorex adalah elemen pemanasan berprestasi tinggi yang direka untuk penjanaan suhu tinggi seragam di dalam relau vakum. Pilih Semicorex untuk kepakarannya dalam penyelesaian grafit yang berturut-turut, memberikan kestabilan terma unggul dan prestasi jangka panjang yang disesuaikan dengan keperluan perindustrian anda.*

Baca LagiHantar PertanyaanRod elektrod grafit

Rod elektrod grafit Semicorex adalah komponen grafit kemelut tinggi yang digunakan sebagai elemen pemanasan teras dalam relau vakum. Pilih Semicorex untuk kualiti bahan yang tidak dapat ditandingi, pemesinan ketepatan, dan prestasi yang boleh dipercayai dalam persekitaran vakum suhu tinggi.*

Baca LagiHantar PertanyaanPlat atas grafit

Plat atas grafik Semicorex adalah lekapan yang direka bentuk dengan ketepatan yang direka untuk pengendalian botol kaca panas yang selamat dan boleh dipercayai dalam persekitaran pembuatan suhu tinggi. Pilih Semicorex untuk kualiti bahan yang tidak dapat ditandingi, keupayaan pemesinan adat, dan prestasi konsisten yang dipercayai oleh pengeluar kaca terkemuka di seluruh dunia.*

Baca LagiHantar PertanyaanGrafit crucibles

Semicorex grafit crucibles direka bentuk untuk kestabilan haba yang luar biasa dan kawalan pencemaran dalam proses pertumbuhan kristal semikonduktor. Pilih crucibles grafit kami untuk kesucian, prestasi, dan kebolehpercayaan yang tidak dapat ditandingi dalam pertumbuhan kristal semikonduktor. *

Baca LagiHantar Pertanyaan