- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Grafit isostatik Pengilang, Pembekal, Kilang

- View as

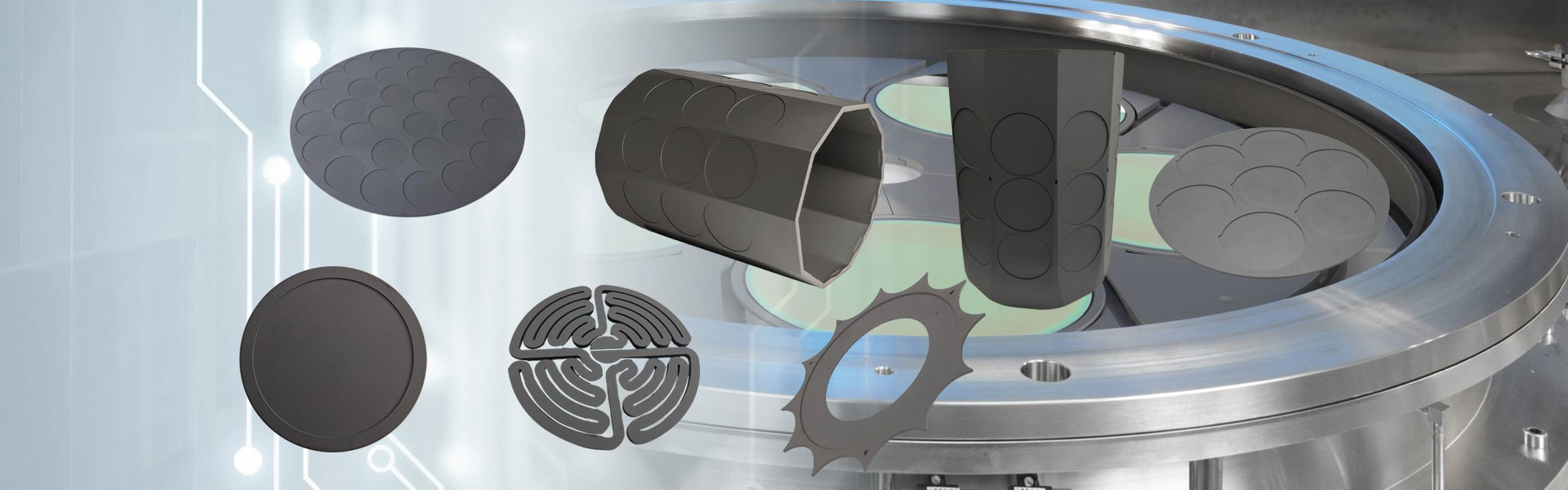

Grafit Chuck

Semicorex Graphite Chuck adalah komponen penting dalam pembuatan polysilicon, digunakan secara meluas dalam industri solar. Memandangkan permintaan untuk wafer silikon kemelut tinggi meningkat, keperluan untuk alat pemprosesan berprestasi tinggi seperti chucks graphite telah menjadi penting. Dikeluarkan dari grafit khusus kemelut tinggi, chuck grafit kami direka untuk menahan suhu yang melampau, pendedahan kimia, dan tekanan mekanikal sambil mengekalkan kestabilan dimensi.*

Baca LagiHantar PertanyaanPemutar dan Aci Grafit

Pemasangan pemutar dan aci grafit semicorex adalah bahagian penting yang kebanyakannya digunakan untuk penyahgas dalam peleburan aloi aluminium dan aluminium.

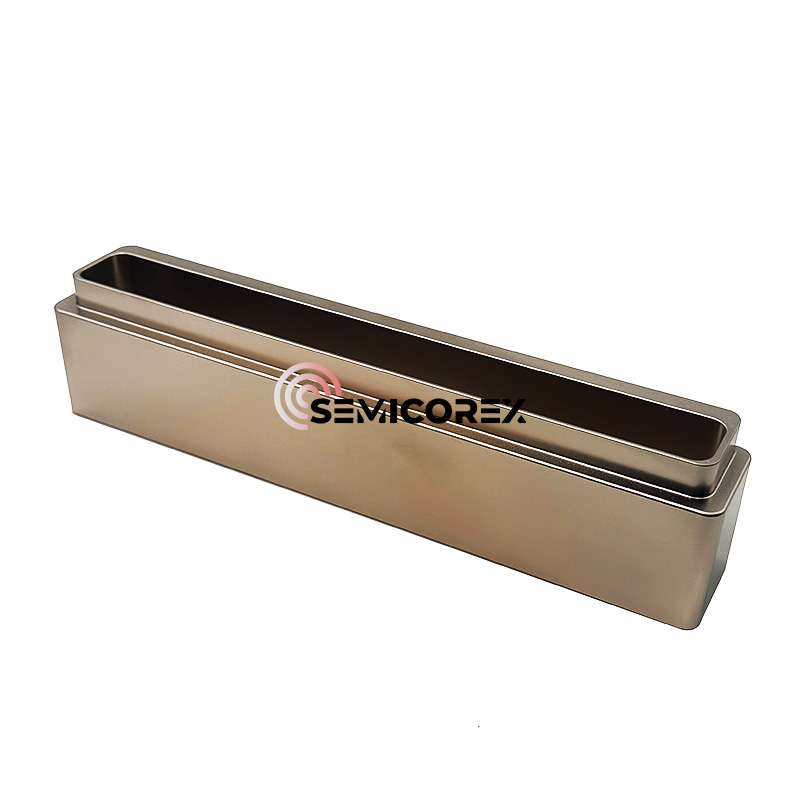

Baca LagiHantar PertanyaanPerisai Haba Grafit

Untuk memastikan keberkesanan pemprosesan dalam persekitaran yang keras, Semicorex Graphite Heat Shields dibuat dengan bahan grafit premium dan teknologi pembuatan termaju.

Baca LagiHantar PertanyaanElemen Perindustrian Pemanasan Grafit

Elemen industri pemanasan grafit semicorex adalah salah satu bahagian terpenting dalam relau pensinteran vakum suhu tinggi. Ia penting untuk pelbagai proses terma kerana kualiti materialnya yang canggih.

Baca LagiHantar PertanyaanSesendal Grafit

Sesendal Semicorex Graphite, dengan ciri-ciri bahan yang unik dan kebolehsuaian, memainkan peranan penting dalam meningkatkan prestasi dan jangka hayat sistem mekanikal, menekankan kepentingannya dalam proses kejuruteraan dan pembuatan moden.

Baca LagiHantar PertanyaanCincin Grafit

Keupayaan Semicorex Graphite Ring untuk menahan keadaan yang melampau dan kemudahan pemasangan menjadikannya komponen yang amat diperlukan dalam industri seperti hidraulik, pneumatik dan penukar haba.

Baca LagiHantar Pertanyaan